“Until now, gaskets were primarily designed to solve a technical problem. With the KLINGER Gaja, we have taken a different approach and asked ourselves how we could make existing solutions with a proven track record more environmentally friendly.”

A New Level of Sustainability with KLINGER Gaja

By KLINGER GPI | 12/18/2024

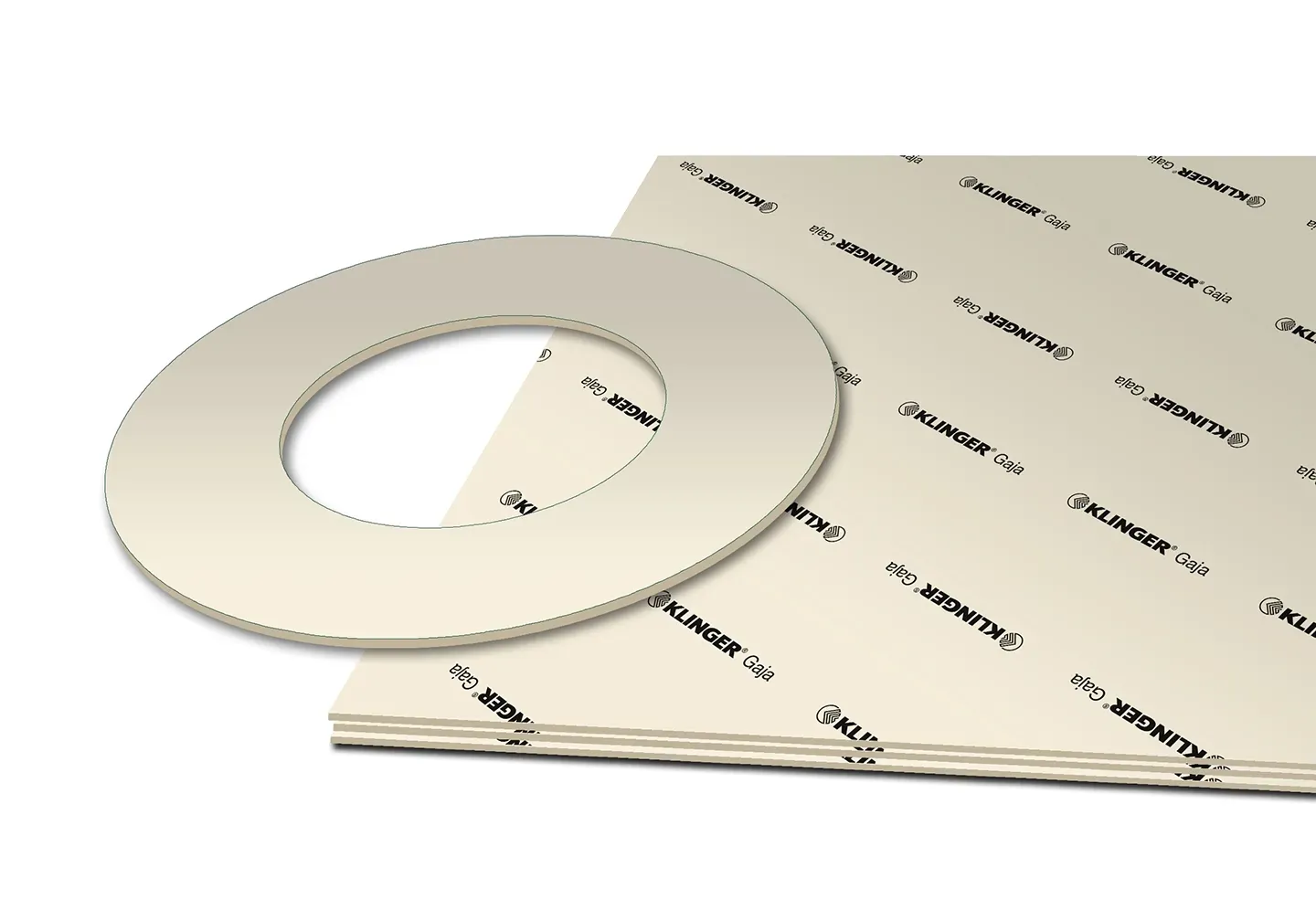

The use of sustainable raw materials is at the heart of the new KLINGER Gaja gasket. With its outstanding eco-balance, this new product helps companies meet their climate targets.

Gaia, the oldest goddess of Olympus, was worshiped in ancient Greece as the creator of the universe and our planet. As Mother Earth, care for nature an sustainability would have been close to her heart. Ans so it is with us. Which is why our product developers have looked to classical mythology in choosing a name for their new KLINGER Gaja - the first gasket made of raw materials chosen for their low environmental impact.

The sustainable gasket

As well as being Head of Product Development at KLINGER Dichtungstechnik, Stephan Piringer is the company’s HSE Manager and, as such, is concerned about sustainability.

With KLINGER Gaja, his team came up with the answer: a universally usable gasket that has all the technical properties of a standard gasket as well as having added value for the environment.

Materials from nature

This value comes from the raw materials, which are largely not of fossil origin and therefore have an unprecedented ecological balance. The key constituents of the KLINGER Gaja gaskets are natural rubber, cellulose fibers, bio-circular silica, and untreated natural mineral fillers. These materials are largely renewable and can be sustainably sourced. The additional substances used in producing some of the gaskets are also chosen for their low environmental impact: no plasticizers, mineral oils or anti-aging agents are used.

Improved eco-balance - not just for customers

The sustainability of KLINGER Gaja is reflected in its looks: Unlike other gaskets, it has not been colored, further boosting its environmental credentials. It is also for this reason that KLINGER Dichtungstechnik is using bio-ethanol as a solvent in the production of KLINGER Gaja. “This makes us pioneers in sustainability and enables us to already supply our customers with products that reduce their ecological footprint,” says Stephan. In preparation for the product’s presentation at this year’s Achema trade fair, KLINGER has already produced its first series of sealing sheets. Around one ton of the sheet material is already in stock.

Forward-looking and certified

Stephan is confident that a sustainable sealing product like KLINGER Gaja will catch the attention of forward-looking and ESG-oriented industries. Designed for non-critical media such as water, oils, fuels, hydrocarbons, inert gases and alcohol at moderate temperatures, the gasket is certified to DIN DVGW and TA-Luft and is DNV GL approved.

Fact box

Did you know ...

» ... that KLINGERSIL gaskets are colored so that they can be identified even without a legible type designation? The different color codes, made up of the gaskets’ colored front, back and cross-section, stand for their product designations. That’s why the gaskets are always shown from both sides in product catalogs.

» ... that 15 percent of the gasket materials used at KLINGER Dichtungstechnik are recycled? This is done by collecting the offcuts of punched-out material sheets, grinding them and blending the grounds into new gasket materials.

» … that bio-circular silica is produced from rice husks? This waste from food production is available in enormous quantities, making it viable for large-scale upcycling.

Phone: +1 (800) 624-7074

All Rights Reserved | KLINGER GPI